Aluminum is indispensable within the manufacturing realm due to its light-weight, versatility, and cost-effectiveness. There are completely different methods you should utilize to show aluminum inventory into purposeful merchandise, and sheet steel fabricating is only one of them. This course of entails slicing, bending, and becoming a member of aluminum steel sheets to supply helpful elements and parts. Aluminum steel sheet fabrication is eco-friendly, and correct and permits for fast prototyping and manufacturing.

There are various methods to fabricate aluminum steel sheets. The one you employ relies on what you are attempting to realize and your undertaking necessities. This text will clarify the method of aluminum sheet fabrication, the way it works, and a few widespread aluminum steel grades you should utilize.

What’s Aluminum Sheet Steel Fabrication?

Aluminum sheet steel fabrication is the method of changing aluminum sheets into numerous sizes and styles. It could contain mechanical deformation or the addition and elimination of supplies. The tip merchandise are helpful 2D or 3D objects which might be light-weight and robust.

How does Aluminum Sheet Steel Fabrication Work?

Aluminum sheet steel fabrication is a mix of assorted methods and processes. Let’s clarify the way it works utilizing the three steps beneath

Preparation

- The primary stage is to pick out probably the most applicable grade of aluminum sheet.

- Thereafter, you clear off dust and particles utilizing a water or alkaline-based cleanser.

- You then sketch the design you wish to replicate. You are able to do this manually or with the help of Laptop-aided design (CAD) software program.

Fabrication

- The subsequent step is to manufacture the aluminum sheet to get the specified design and form.

- You do that by slicing, forming, or becoming a member of. Most occasions, you could have to make use of greater than a single approach to acquire the specified outcome.

Ending

- After getting your fabricated aluminum elements, the subsequent step is to hold out numerous post-processing operations as wanted.

Notice: Aluminum is suitable with many ending choices together with anodizing, powder coating, and bead blasting.

Key Processes in Aluminum Sheet Steel Fabrication

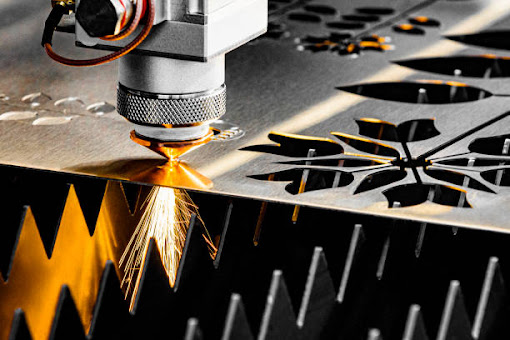

‘Technique of utilizing a plasma cutter to supply intricate designs on a sheet of aluminum’

There are various methods to manufacture aluminum sheets. These methods have completely different benefits and distinctive targets. It is very important perceive each and decide its suitability earlier than utilizing any. The commonest processes in aluminum sheet steel fabrication embrace

Reducing entails the elimination of fabric from the aluminum sheet. Most slicing methods contain a shear power whereas others might not.

Reducing with shearing

Shearing entails putting the aluminum sheet in between two blades. Because the steel inventory is available in contact with the blades, it’s break up in a straight line into smaller items. Notice that for this to happen, the power should be larger than the shear power of the aluminum sheet. Shearing is straightforward to hold out and cheaper. Nonetheless, it comes with restricted accuracy and will not be appropriate for functions with tight tolerances.

Reducing with out shearing

There are different slicing approaches that don’t contain blades and a shear power. You possibly can perform this course of utilizing laser slicing, plasma slicing, or waterjet slicing techniques.

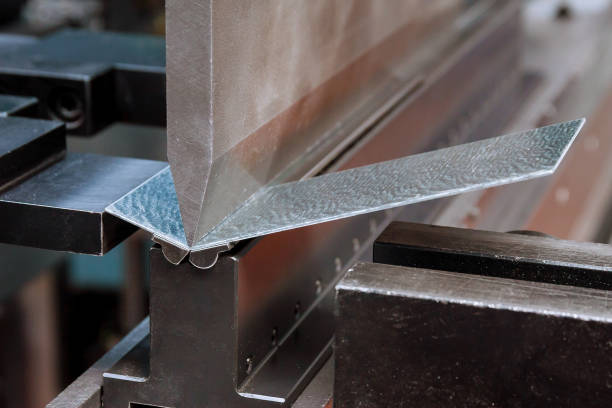

Bending is a deformation course of that entails the applying of power to change the form of a sheet of aluminum. It makes use of a press brake software to exert stress to supply new angles often U or V formed. Bending enhances productiveness and is right for very skinny sheets. Moreover, it’s a quick course of as a bend takes just some seconds.

Curling is a forming operation that creates a curved edge out of an aluminum sheet. The ultimate half has a hole ring that eliminates sharp edges and makes it safer to deal with. Notice that you will need to perform the curling course of progressively. You first pre-bend earlier than utilizing a curling die to progressively form the workpiece.

Hemming is much like curling however they don’t seem to be the identical. In hemming, you fold the aluminum sheet over itself to extend the sting power. This flat folded edge is generally used for structural reinforcement. There are two predominant forms of hem; open and closed hem. An opened hem permits for a little bit of area within the hem whereas a closed hem doesn’t.

Stamping makes use of a die and specialised tooling to form a clean aluminum sheet. To hold out stamping, step one is to design a die primarily based on what you need the ultimate half to seem like. Place the sheet in between the die halves and shut. Apply power and stress to deform the steel sheet and form it primarily based on the die’s contours.

Welding makes use of warmth and stress to affix two or extra aluminum sheets collectively. In sure situations, it’s crucial so as to add a filler materials to create a stronger joint. There are completely different welding strategies accessible with MIG and TIG welding being the commonest. Welding creates a everlasting joint that isn’t reversible.

Fastening is a more cost effective becoming a member of course of when in comparison with welding. It entails the usage of fasteners akin to rivets, bolts, and screws to carry aluminum elements collectively. Fastening is straightforward to hold out and doesn’t require expert labor. Nonetheless, it provides to the general weight of the part and drilled holes might have an effect on the structural integrity of the half.

Kinds of Aluminum Utilized in Sheet Steel Fabrication

There are various grades of aluminum steel accessible. Nonetheless, not all are appropriate for sheet steel fabrication. The next are the commonest sorts used

It’s an alloy that incorporates a excessive content material of magnesium, often 2.5% and 0.25% chromium. It’s corrosion-resistant with average power and you’ll simply work on it. 5052 is an ideal candidate for fast prototyping and small-batch manufacturing. Nonetheless, specialists advise in opposition to warmth treating this alloy to extend its hardness and power.

The 6061 aluminum alloy is often known as ‘alloy 61S’. It’s composed of 0.9% magnesium, 0.7% silicon, and 0.6% iron as the key alloying parts. It has wonderful formability and weldability properties. Moreover, it’s ductile and you’ll perform numerous warmth remedy strategies for the next power degree. It’s very best when manufacturing automotive elements and constructing facades.

A typical identify for this aluminum alloy is ‘plane grade’. It’s stronger than the kinds beforehand described. 7075 aluminum alloy incorporates zinc as the first alloying ingredient with traces of magnesium, copper, and silicon. It has average formability and reveals good resistance to fatigue. This aluminum alloy grade ought to be your go-to when developing plane buildings.

The 3003 aluminum alloy is a general-purpose alloy that has manganese as the key alloying ingredient. The excessive manganese content material reinforces its hardness and toughness. It’s appropriate for out of doors functions due to its wonderful resistance to atmospheric corrosion. You’ll discover it in storage tanks, chemical gear, and corrugated roofing.

What Industries Use Fabricated Aluminum Sheet Components?

Many industries use aluminum for sheet steel fabrication. It’s the most plentiful steel on earth and weighs one-third of metal. Frequent industries that use fabricated aluminum sheet parts embrace

Medical Trade

Medical elements producers use fabricated aluminum sheets extensively. It’s helpful when making diagnostic, dental, and surgical units. This method presents a brief lead time and produces versatile and sturdy parts. Moreover, aluminum is corrosion-resistant and the elements don’t degrade when in touch with bodily fluids.

Aerospace and Aviation

Fabricated aluminum elements present a wonderful strength-to-weight ratio. This property is vital within the aerospace and aviation business. The lighter the half, the lesser the gasoline consumption. You’ll discover it in lots of structural functions akin to fuselages and wings.

Vitality Sector

Aluminum sheets additionally play a task within the vitality business. It’s inexpensive and most grades have a low carbon content material. Fabricated aluminum is beneficial when constructing photo voltaic panels, electrical autos, and wind generators.

Army and Protection

Fabricated aluminum sheets are an vital a part of the navy and protection sector. The ultimate merchandise are light-weight, may be simply dealt with, and soak up influence. It has functions when manufacturing weapons, mines, and navy autos.

Conclusion

Aluminum sheet steel fabrication entails manipulating aluminum sheets to supply sturdy and purposeful parts. There are various methods to go about this and the approach you employ relies on what you wish to obtain. This information has mentioned aluminum sheet fabrication in-depth, probably the most appropriate supplies you should utilize, and their functions in manufacturing industries.

Supply hyperlink