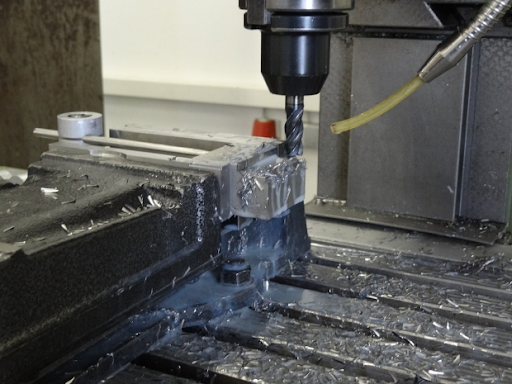

Fast plastic prototyping is significant for organizations that want to develop their concepts shortly within the fast-paced world of product growth. CNC drilling, one in all many strategies utilized in plastic prototypes, ensures precision and effectivity. When is CNC drilling utilized in fast plastic prototyping? CNC drill is barely mandatory in sure situations, and this text discusses its advantages.

CNC Drilling’s Function

The method’s accuracy permits for constant gap sizes and areas. Fast plastic prototyping makes use of CNC drilling to create holes for exact parts like wiring, fasteners, and so on. CNC drilling processes could also be scaled up for mass manufacturing, guaranteeing homogeneity from prototype to closing product. CNC drilling can scale to suit your undertaking’s wants, from one prototype to 1000’s. This meets undertaking necessities.

Fast Plastic Prototyping: When Is CNC Drilling Used?

Creating Complicated Geometries

CNC drilling is finest for detailing and ending prototypes with intricate geometries and exact holes. This expertise permits for intricate particulars that will be laborious to drill with standard strategies. CNC machines’ multi-axis drilling allows them to drill sophisticated angles and kinds. This experience is important for prototyping non-standard gap placements.

Excessive-Frequency Prototyping

When creating many prototypes, CNC drilling ensures gap placement and measurement are constant. We keep consistency throughout quite a few models from begin to end. Uniformity is important for prototyping performance and match. CNC drilling is quicker than hand drilling, making it perfect for high-volume prototyping duties that require velocity.

Strengthening Construction Integrity

The position of holes in a prototype can have an effect on its structural integrity. CNC drilling ensures holes are drilled exactly, holding the prototype’s power and sturdiness.

Plastics require totally different drilling strategies, subsequently materials issues. CNC drilling could also be adjusted to suit the wants of many plastic supplies, guaranteeing the prototype’s integrity.

Mechanical Parts within the Complete

CNC drilling offers the precision wanted to align and match mechanical parts like screws, nuts, and digital connectors in a prototype.

CNC drilling makes gap sizes and positions simpler to regulate, making prototypes adaptable to new parts and designs. Simple customization requires adjustment.

Excessive rigidity

CNC drilling is thought for its precision, permitting holes to be drilled exactly the place wanted. This degree of accuracy is important for fast plastic prototyping since even little deviations can have an effect on functioning and aesthetics.

For uniformity, CNC drilling’s computer-controlled nature assures that every gap is identical measurement and placement amongst prototypes. That is essential for consistency.

Effectivity and velocity

CNC drilling machines could also be programmed and arrange shortly, decreasing start-up time. This velocity is helpful for fast prototyping, the place time-to-market is turning into extra essential. CNC drilling can shortly course of massive quantities of labor, making it perfect for duties that require many prototypes or parts.

Adaptation

CNC drilling could also be used on a number of plastic supplies, from pliable polymers to inflexible plastics. This software can be utilized for a lot of prototype jobs due to its adaptability. CNC machines can drill holes at varied angles and depths, permitting them to assemble intricate designs that handbook drilling can be laborious to attain.

Economical and Helpful

The automation of CNC drilling reduces handbook labor, which might decrease manufacturing prices. CNC drilling’s precision lowers errors, rework, and materials prices.

Higher Construction and Power

CNC drilling permits exact gap placement, defending a prototype’s structural integrity. Right gap placement ensures its sturdiness and usefulness. CNC drilling can swiftly change gap sizes and positions with out affecting prototype power.

Integrating Different Techniques and Procedures

CNC drilling could also be seamlessly built-in with different CNC machining processes like milling and slicing to create sophisticated prototypes.

The precision of CNC drilling ensures that mechanical parts like screws and connectors match exactly throughout the prototype, making meeting and testing simpler.

CNC drilling in fast plastic prototyping lets companies make high-quality, operational prototypes shortly and cheaply. This facilitates product creation and innovation.

FAQs

What’s the CNC drilling sort?

Laptop-controlled drilling makes use of a drill bit to exactly drill holes.

Why is CNC drilling essential in fast plastic prototyping?

CNC drilling is important for prototyping high quality, consistency, and effectivity.

Can CNC drill all plastics?

Certainly, laptop numerical management drilling can work with many plastics, accommodating a variety of fabric properties.

How can CNC drilling improve prototype structural integrity?

Laptop numerical management drilling ensures exact gap placement and materials consideration, preserving the prototype’s power and longevity.

Conclusion

CNC drilling is important for fast plastic prototypes the place velocity, precision, and consistency are wanted. CNC drilling ensures that sophisticated geometries, huge volumes of prototypes, structural integrity, and mechanical parts meet specs. CNC drilling permits firms to fabricate high-quality prototypes for product growth.

The publish When Is CNC Drilling Utilized in Fast Plastic Prototyping? appeared first on Vamonde.