A frequency inverter, often known as a variable frequency drive (VFD) or adjustable-speed drive, is an digital machine that controls the velocity and torque of electrical motors by various the frequency and voltage of the facility provided to the motor. Frequency inverters are extensively utilized in industrial purposes, business gear, and even some shopper merchandise as a result of they provide important vitality financial savings, improved motor management, and enhanced course of automation.

On this article, we’ll discover how frequency inverter work, their key elements, and the advantages of utilizing them in numerous purposes.

How a Frequency Inverter Works

Electrical motors, notably induction motors, function at a velocity that’s straight proportional to the frequency of {the electrical} energy they obtain. In a typical alternating present (AC) energy system, the frequency is fastened, often at 50 Hz or 60 Hz, relying on the area. A frequency inverter permits for the adjustment of this frequency, and thus the motor velocity, with out altering the motor itself.

Right here’s how a frequency inverter sometimes works:

1. AC to DC Conversion (Rectifier Stage)

When energy enters the frequency inverter, it first passes by way of a rectifier stage, which converts the alternating present (AC) from the grid into direct present (DC). This step ensures that the machine has a gradual provide of electrical energy to work with, as DC is extra simply managed for the aim of various output frequency.

2. DC Filtering

As soon as transformed to DC, the electrical energy is smoothed and filtered to make sure it’s steady and prepared for the subsequent stage of the method. This helps get rid of any ripples or fluctuations within the present, guaranteeing constant efficiency from the inverter.

3. DC to AC Conversion (Inverter Stage)

Within the last stage, the frequency inverter converts the direct present again into alternating present, however with one key distinction: it modulates the frequency and voltage of the AC to manage the motor velocity. This modulation permits the motor to function at a variety of speeds, relying on the precise software wants.

By adjusting the output frequency, the inverter can enhance or lower the velocity of the motor, providing extra exact management over the machine or gear being operated.

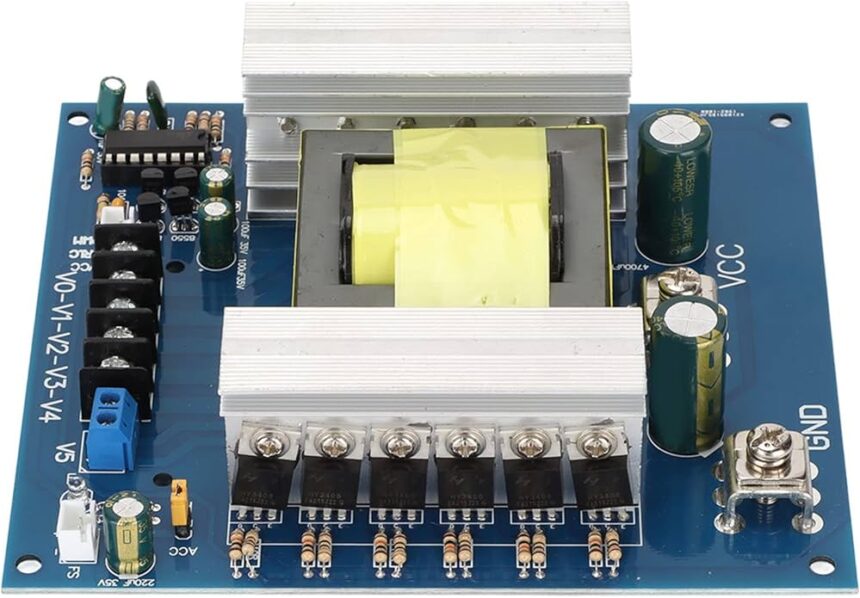

Key Elements of a Frequency Inverter

A frequency inverter sometimes consists of a number of key elements, every enjoying a necessary function in controlling the motor:

- Rectifier: Converts incoming AC energy to DC.

- DC Hyperlink: That is the intermediate part the place the DC is smoothed and filtered.

- Inverter: Converts DC again into AC on the desired frequency and voltage.

- Management Unit: This a part of the inverter receives enter from sensors or operators and adjusts the output frequency and voltage accordingly.

Advantages of Utilizing Frequency Inverters

1. Power Financial savings

Probably the most important benefits of utilizing a frequency inverter is the potential for vitality financial savings. Electrical motors working at full velocity on a regular basis can eat numerous vitality, particularly in methods the place full energy will not be at all times crucial. By controlling the motor velocity with an inverter, vitality consumption may be optimized, resulting in decrease vitality payments and lowered environmental influence.

As an example, in HVAC methods, frequency inverters enable followers and pumps to run at lowered speeds when full capability will not be required, saving vitality with out compromising efficiency.

2. Exact Motor Management

Frequency inverters supply extra exact management over motor velocity, which is essential in lots of industrial processes. By regulating the frequency and voltage provided to the motor, operators can obtain easy acceleration and deceleration, keep away from sudden jerks, and reduce put on and tear on mechanical elements.

That is particularly useful in purposes like conveyor methods, the place variable velocity is required to move items at completely different charges relying on demand or manufacturing ranges.

3. Prolonged Motor Lifespan

Working an electrical motor at a relentless, excessive velocity can result in extreme put on and warmth buildup, which may shorten the motor’s lifespan. Frequency inverters enable motors to run at optimum speeds for the duty at hand, decreasing mechanical stress and lengthening the lifetime of each the motor and related gear.

Moreover, the soft-start characteristic supplied by frequency inverters reduces the inrush present sometimes skilled throughout motor startup, additional defending the motor from injury.

4. Enhanced Course of Management

Many industries depend on advanced equipment that requires exact management to function effectively. Frequency inverters enable for fine-tuned changes to motor velocity, which is particularly helpful in industries like manufacturing, the place exact timing and velocity changes are important to sustaining product high quality.

In industrial automation, frequency inverters may be built-in with programmable logic controllers (PLCs) to create extremely automated methods with superior management capabilities.

5. Lowered Mechanical Put on

In purposes involving mechanical gear like pumps, followers, or compressors, frequency inverters assist cut back mechanical put on by eliminating the necessity for mechanical throttling or dampers to manage move charges. As an alternative, the motor velocity is adjusted straight, leading to smoother operation and lowered pressure on mechanical elements.

Functions of Frequency Inverters

Frequency inverters are utilized in a variety of purposes throughout numerous industries, together with:

- HVAC Programs: For controlling the velocity of followers, pumps, and compressors, optimizing vitality use in heating, air flow, and air-con methods.

- Manufacturing: Utilized in conveyor belts, milling machines, and different manufacturing gear for exact velocity management and automation.

- Water and Wastewater Therapy: In pumps and aerators to regulate move charges and save vitality.

- Elevators and Escalators: To offer easy acceleration and deceleration, enhancing passenger consolation and security.

- Renewable Power Programs: In solar energy installations, frequency inverters are used to transform DC from photo voltaic panels to AC for grid use.

Conclusion

Frequency inverters play a vital function in enhancing vitality effectivity, offering exact motor management, and lengthening the lifespan of electrical motors. Whether or not for industrial purposes or business settings, they provide a flexible answer for controlling motor velocity and optimizing efficiency. In case you’re seeking to cut back vitality consumption, enhance gear lifespan, or improve course of automation, a frequency inverter is a wonderful funding for each small and large-scale operations.

Supply hyperlink