Within the complicated and dynamic world of metalworking, press brakes occupy a cornerstone place, pivotal in shaping uncooked metallic into intricate, purposeful elements. These machines are crucial throughout quite a few industries, from automotive to aerospace, owing to their skill to ship precision and effectivity in bending metallic sheets into varied types. Whether or not the duty entails establishing car panels, fabricating protecting digital enclosures, or assembling architectural frameworks, the suitable alternative of new press brakes on the market can considerably optimize each effectivity and accuracy in manufacturing.

The basic operation of press brakes integrates managed drive with actual alignment, producing bends that meet rigorous requirements of precision and consistency. This functionality is essential for advancing modern design practices and sustaining economically viable manufacturing operations. A deep understanding of press brake functionalities permits metallic fabrication professionals to unlock new manufacturing high quality and pace ranges, securing aggressive benefits in an trade characterised by speedy development and intense competitors.

Sorts of Press Brakes

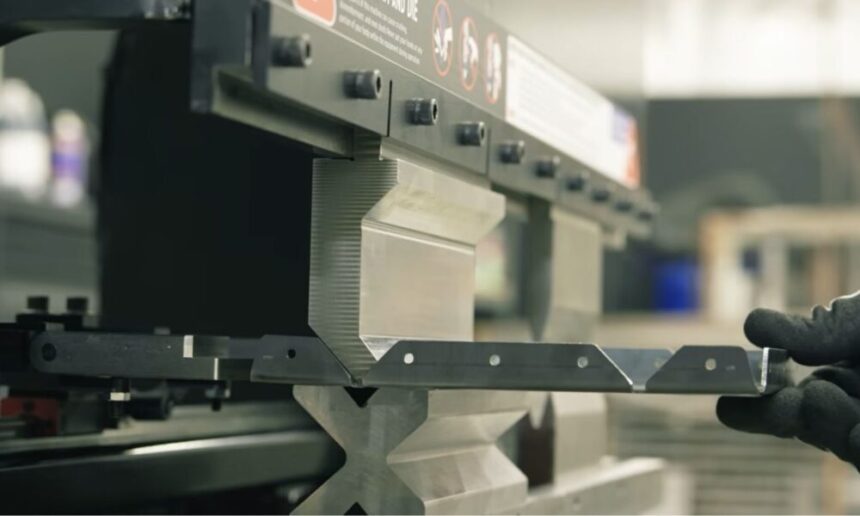

Press brakes are versatile machines in varied configurations, every tailor-made to meet particular industrial wants. Mechanical press brakes are prized for his or her speedy operation, making them very best when time effectivity is crucial. Alternatively, hydraulic press brakes are celebrated for his or her superior management, making them appropriate for processes requiring cautious manipulation of heavier, extra resilient supplies. CNC (Laptop Numerical Management) press brakes signify the peak of technological development, utilizing refined software program to handle bending processes with distinctive precision and minimal want for handbook oversight.

The choice on which sort of press brake to deploy can profoundly influence manufacturing effectivity and product high quality. The important thing to attaining optimized operations and distinctive product high quality lies in aligning the machine’s capabilities with the challenge’s particular necessities. This decision-making course of necessitates a complete analysis of challenge wants and an astute understanding of every press brake kind’s distinctive advantages, making certain the chosen gear is ideally suited to the duty.

Functions in Trade

Press brakes exhibit distinctive versatility, evidenced by their widespread utility throughout a number of industries. These machines are basic to producing every little thing from delicate digital elements to strong and dependable automotive and aerospace components. They allow producers to effectively create small, detailed items and enormous, sturdy panels important for car and infrastructure initiatives. An in-depth understanding of leveraging press breaks inside varied industries empowers companies to optimize their manufacturing processes successfully. By considerably lowering waste and growing throughput, these machines deal with fast manufacturing challenges whereas supporting the execution of complicated, modern designs. This adaptability strengthens present operations and encourages exploration into new realms of metallic fabrication; driving continued innovation and progress all through the trade.

Improvements in Press Brake Expertise

Developments in expertise are quickly remodeling the press brake panorama, turning conventional metalworking processes into extremely environment friendly and complex methods. Fashionable press brakes now incorporate digital controls and synthetic intelligence, significantly enhancing precision whereas lowering the chance of human error. These cutting-edge improvements have considerably elevated productiveness, granting industries unparalleled management and suppleness of their manufacturing processes.

Moreover, these technological enhancements present operators with better oversight, permitting them to deal with complicated duties with heightened ease and precision. As clever expertise continues to be built-in into press brakes, future developments promise even additional enhancements in effectivity and customization, establishing a strong basis for ongoing technological progress that aligns with evolving trade calls for.

Upkeep and Security Concerns

Guaranteeing that press brakes function at their highest potential requires a strict and proactive method to upkeep and security. Frequent examinations and proactive maintenance are essential to forestall sudden gear breakdowns and keep constant, steady functioning. Moreover, complete coaching packages for operators are crucial to maximizing gear capabilities whereas making certain a secure working atmosphere. Correctly maintained press brakes guarantee the manufacturing of high-quality merchandise and safeguard the workforce, underscoring the significance of rigorous upkeep practices and ongoing talent growth. Adherence to trade greatest practices in upkeep and security displays an unwavering dedication to operational excellence and the well-being of employees, emphasizing the crucial position of preventive measures in sustaining environment friendly and safe manufacturing operations.

Financial Influence of Press Brakes

Integrating press brakes into manufacturing traces can considerably cut back manufacturing prices because of sooner manufacturing cycles and minimized materials waste. These machines improve financial effectivity by optimizing useful resource allocation and enabling companies to fulfill growing market calls for with out compromising high quality or supply pace. Past fast value financial savings, press brakes contribute to scalable and optimized manufacturing processes, fostering long-term sustainability and progress. This financial influence empowers firms to increase their operations and enhance competitiveness in a world market, positioning organizations for continued success and innovation as they navigate an ever-evolving monetary panorama.

Future Traits in Metalworking with Press Brakes

The way forward for metalworking is evolving rapidly, pushed by ongoing developments in automation and AI applied sciences inside press breaks. These developments promise to boost manufacturing operations by making them extra modern, adaptable, and environmentally sustainable. Embracing these traits will likely be essential for industries that keep a aggressive edge and capitalize on rising innovation alternatives. Integrating rising applied sciences guarantees to encourage new approaches and techniques in metalworking, making certain that press breaks proceed to steer innovation inside the sector. As new developments grow to be seamlessly integrated into press brake expertise, the trade can anticipate a future outlined by elevated effectivity, adaptability, and sustainability in all features of metalworking operations.

The submit Environment friendly Metalworking: The Important Function of Press Brakes appeared first on Vamonde.