Machine monitoring has emerged as a transformative power, reshaping how industries understand and handle machine operations. By harnessing real-time information acquisition and evaluation, machine monitoring optimizes manufacturing strains, minimizes sudden halts, and enhances productiveness. The expertise behind machine monitoring software program with predictive upkeep options takes predictive capabilities additional, enabling preemptive troubleshooting that conserves assets and improves operational fluidity.

This technological evolution traces again to the daybreak of commercial automation, which operated predominantly on reactive upkeep methods. The present panorama embraces a proactive method, the place data-driven insights dictate upkeep schedules and avert potential downtimes earlier than they escalate into essential failures.

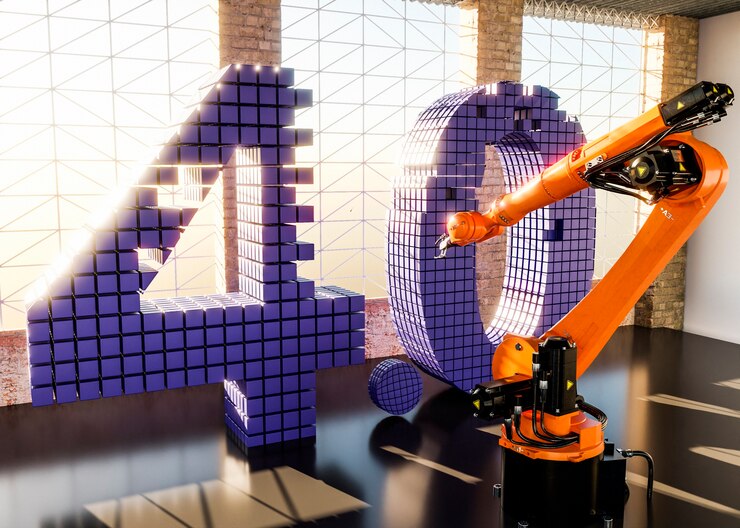

The Significance of Machine Monitoring in Business 4.0

Important breakthroughs in automation, connectivity, and information sharing are hallmarks of the fourth industrial revolution, or Business 4.0. Machine monitoring stands on the core of this revolution. It enhances not solely operational effectivity but additionally promotes a sustainable industrial surroundings. In response to Forbes, the widespread adoption of Business 4.0 practices has remodeled conventional industries into dynamic and responsive entities geared up to face the challenges of the trendy market.

The deployment of such superior methods helps the widespread integration of sensible factories, the place machines talk seamlessly, providing elevated transparency and effectivity throughout operations.

Chopping-edge applied sciences in Machine Monitoring

On the coronary heart of machine monitoring lies a convergence of pioneering applied sciences. The Web of Issues (IoT) equips machines with sensors that seize essential operational information. In distinction, synthetic intelligence (AI) and machine studying algorithms sift by means of this information, producing insights that drive decision-making processes. It’s not possible to overestimate the worth of predictive upkeep and real-time analytics. These options empower companies to transition from reactive approaches to proactive upkeep, mitigating dangers and amplifying productiveness.

Furthermore, developments in sensor expertise and the proliferation of cloud computing companies have revolutionized how information is saved and accessed. These technological strides guarantee important efficiency metrics are accessible anytime, anyplace, fostering an knowledgeable and responsive operational surroundings.

Challenges and Options in Implementing Machine Monitoring

The street to implementing machine monitoring methods is fraught with challenges, primarily revolving round excessive setup prices and the complexity of knowledge administration. Many companies’ preliminary {hardware}, software program, and coaching expenditures might be excessive. Nevertheless, industries more and more acknowledge these methods’ long-term financial savings in operational prices and useful resource optimization.

Strategic planning and phased implementation are important ways in overcoming these hurdles. The MIT Expertise Assessment highlights the significance of adopting a strategic method, advocating for incremental integration and prioritization of assets to streamline adoption processes.

The Human Ingredient: Coaching and Adoption

Profitable integration of machine monitoring applied sciences extends past the technological realm—it calls for a workforce geared up with the information and abilities to maximise these methods. Complete coaching packages are indispensable, guaranteeing that staff perceive monitoring methods’ operations and advantages. The capability of the workforce to completely make the most of these applied sciences is improved by fostering a tradition of ongoing studying and adaptation.

Selling worker buy-in reduces resistance to alter and encourages a smoother transition, enabling organizations to use the benefits machine monitoring affords absolutely.

Future Developments and Improvements

The way forward for machine monitoring is promising, as it’s poised for important developments pushed by modern applied sciences. One of many standout developments is blockchain, which has the potential to rework the panorama of knowledge safety and integrity. Blockchain can improve stakeholder belief whereas reducing the dangers of knowledge breaches and manipulation by decentralizing information storage and providing clear, tamper-proof data. It’s notably helpful in industries the place information accuracy is essential, resembling manufacturing and provide chain administration.

Along with blockchain, edge computing is making appreciable strides in revolutionizing how information is processed and managed. By bringing information processing nearer to the supply—whether or not it’s equipment on the manufacturing facility flooring or sensors in distant areas—edge computing permits real-time evaluation and decision-making. Companies can optimize their operations higher due to the faster response occasions and decrease latency. Combining these applied sciences improves system efficiency and simplifies information administration, which raises output and lowers working bills.

As these applied sciences evolve, machine monitoring methods will turn out to be extra refined, incorporating options that improve predictive upkeep and operational effectivity. Firms proactively adopting these improvements will acquire a aggressive edge within the market. By leveraging rising applied sciences, these organizations can obtain superior operational capabilities, resulting in improved outcomes resembling lowered downtime, enhanced product high quality, and better useful resource effectivity.

In the end, companies prepared to adapt to and embrace these technological developments will enhance their backside line and place themselves as leaders in an more and more aggressive business. The proactive integration of blockchain, edge computing, and different rising applied sciences will probably be essential in shaping the way forward for machine monitoring and industrial practices total.

Conclusion: Making ready for a Related Future

The mixing of machine monitoring inside the framework of Business 4.0 signifies a progressive shift in the direction of extra knowledgeable, environment friendly, and sustainable industrial processes. Companies can thrive within the evolving technological panorama by understanding its pivotal position, adopting cutting-edge applied sciences, and tackling implementation challenges head-on.

In the end, probably the most important funding an organization could make is in its individuals, making ready them to embrace these applied sciences and innovate with them. Because the business shifts in the direction of an interconnected future, proactive adaptation will guarantee sustained progress and aggressive benefits within the market.

The publish The Subsequent Industrial Revolution: Machine Monitoring and Business 4.0 appeared first on Vamonde.